Transitioning From VMI to CMI: How Electronic Shelf Labels Can Save You Money

Both distributors and their customers can save money and increase efficiencies by transitioning from a Vendor-managed inventory (VMI) model to a Customer-managed inventory (CMI) model for replenishment. However, without the correct tools, this transition can prove difficult and more costly. Learn about the benefits of transitioning to CMI and find out how to facilitate a smooth transition using electronic shelf labels (eLabels).

"Instead of relying on the distributor to create orders using VMI once or twice per month, a CMI model allows customers to trigger replenishment directly and whenever needed."

VMI vs. CMI

The term VMI, or Vendor Managed Inventory, refers to a wide range of practices and procedures allowing distributors (a.k.a suppliers or vendors) to help their customers replenish products. In a typical VMI scenario, the vendor will manage the following:

- Creating barcode labels

- Monitoring inventory levels and min/max settings for replenishment

- Making replenishment decisions

- Creating orders

- Delivering products

On the other hand, CMI, or Customer Managed Inventory, usually entails customers using self-service replenishment tools to generate orders themselves. Instead of relying on the distributor to create orders using VMI once or twice per month, a CMI model allows customers to trigger replenishment directly and whenever needed.

Without the right tools, the practice of CMI can quickly become confusing and overwhelming for customers. Manual entry and order creation easily falls through the cracks, which can lead to issues such as stockouts or overstock. On the other hand, moving to a CMI model using the latest technology has the potential to create impactful savings for both the customer and the vendor. Find out how modern tools such as electronic shelf labels can help streamline the transition from VMI to CMI.

"With electronic shelf labels, customers can trigger their own replenishment orders when needed and strategically avoid overstock or stockouts, thus protecting their bottom line."

Benefits of Transitioning from VMI to CMI

Transitioning from a VMI to a CMI model can help both vendors and customers save money. When implemented correctly, a CMI model can run even more smoothly and efficiently than some VMI models.

Customer Benefits

Customer benefits from the transition from VMI to CMI include cost savings and greater control over replenishment. In many cases, distributors may charge up to four times the regular price of an item when supplying VMI services for that item. This is because the distributor is likely sending a person out at regular intervals to perform inventory counts, restock bins, and more. The costs of maintaining this position are significant, and some of that cost naturally falls to the customer.

In addition, CMI models mean that customers gain control over their own replenishment. Customers can trigger their own replenishment orders when needed and strategically avoid overstock or stockouts, thus protecting their bottom line.

Distributor Benefits

From a distributor perspective, transitioning customers to a self-service CMI model for replenishment not only reduces the cost to service those customers, but it also eliminates the need for location restrictions. Without the need to send out a representative for inventory counts and restocking, distributors can extend the reach of their salesforce and operate more efficiently. With the customer triggering their own replenishments, valuable time and resources become available for other priorities.

While these benefits for both vendors and customers are significant, it is crucial to transition to CMI using the appropriate technology for inventory tracking and replenishment.

"For companies working with limited space, eLabels provide an ideal solution."

Streamline CMI Processes with Electronic Shelf Labels

In order to create reliable and accurate replenishment processes in a CMI model, many organizations rely on tools such as electronic shelf labels.

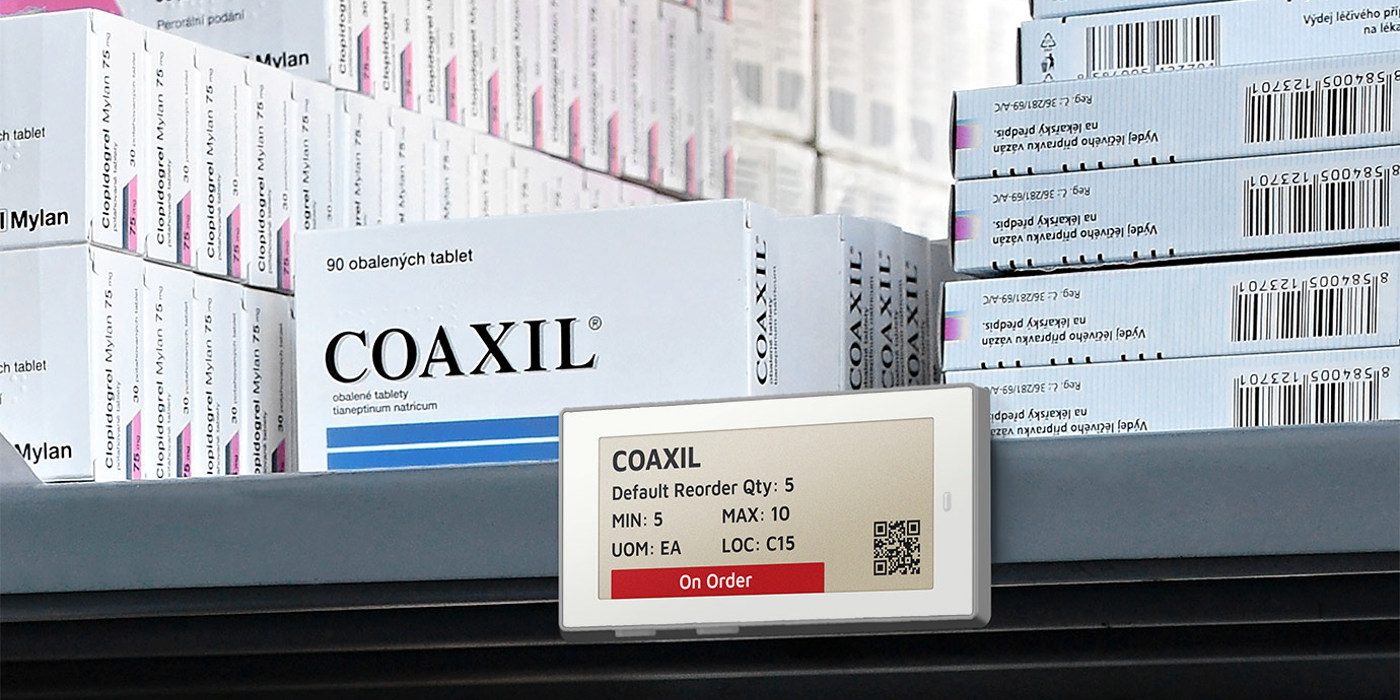

Customers can set up electronic shelf labels, or eLabels, to display important information pertaining to each item, no matter how they are stored. Each item will have its own label, and the label will include information such as:

- The item number and name

- The default order quantity

- The min and max levels

- The item’s unit of measure

- Location information

- A QR code

Whenever a member of the customer’s staff notices that an item’s quantity has fallen below its designated minimum level, all they need to do is press a button underneath the edge of the eLabel. This will automatically trigger an order to the distributor.

Electronic shelf labels are a convenient tool for CMI and self-service replenishment for a variety of reasons.

- Time savings: Eliminating the need for clipboard-and-pencil ordering systems helps customers save time while reducing errors. Automating this process with the simple press of a button means fewer lost orders, forgotten counts, and unexpected stockouts.

- Space savings: While other automated inventory management systems such as SensorBins play a role in many successful CMI models, they also require designated bins and shelf space for each item. For customers working with limited space, eLabels provide an ideal solution.

- Automate replenishment tasks: Customers save time and resources with automated order creation and placement. Instead of trying to jot down item #s correctly, remember item details, and place orders manually, they simply press a button.

- Trigger immediate orders with “on order” safeguards: Customers reduce the risk of stockouts and eliminate the need for overstock with this fast and reliable inventory management system. eLabels display “on order” notices and prevent duplicate ordering, even if users press the button multiple times.

Both distributors and customers can benefit from the transition from CMI to VMI with the appropriate tools. With the power to designate min/max levels and place orders with the quick press of a button, customers gain control and efficiency in their inventory management process. In turn, distributors save on the labor and travel costs required for traditional VMI counts and replenishment.