The Comprehensive Guide to Inventory Audits

What is an Inventory Audit?

An inventory audit is a systematic and strategic process that helps an organization understand their current inventory levels and compare them to their recorded or expected levels. This process helps identify errors and discrepancies, shedding light on any gaps in the everyday inventory management process and paving the way for improvement where necessary. Inventory audits are integral for reporting, forecasting, and allocating future resources.

What Type of Inventory Needs to Be Audited?

At a high level, business inventory falls into 3 categories: raw material, work-in-process, or finished goods. For inventory audits of finished goods, it is important to differentiate between point-of-use inventory and point-of-sale inventory because they require different methods and apps for cycle counting. Point-of-use inventory includes items used in the course of business such as maintenance, repair, and operations material (MRO), industrial products, medical consumable inventory, etc. This article primarily focused on inventory audits of point-of-use inventory.

The High Cost of Inaccurate Inventory Counts

Maintaining inventory accuracy is essential for smooth operations and a high level of customer care. Inaccurate inventory counts can lead to overstocking, which pulls cash away from other priorities, or stockouts, which can be disastrous for both sales and operations.

If you are manage a fulfillment center where 3000 people work everyday packaging ecommerce products, you need to make sure you never stockout of janitorial/sanitation products. In the medical industry, stockouts can compromise patient experiences and even interfere with appropriate care. Stockouts harm the relationship of trust with customers and stakeholders, leading to long-term costs to the business. But buying too much inventory just to ensure you don’t stockout wastes money on inventory and carrying costs.

Regardless of business type, inventory accuracy is essential for reliable financial statements and strategic decision-making processes. Performing error-free inventory audits regularly and investing in the necessary technology to keep accurate inventory counts is well worth it for the long-term benefits.

Types of Inventory Audits

Since every type of organization has different needs and processes, there are various types of inventory audits. For example, a contracting company with a complex and ever-changing stock will need a different inventory audit strategy than a medical clinic. Businesses can optimize inventory levels by selecting the inventory audit type that best aligns with their specific operational goals and needs.

Physical Inventory Counts

Physical inventory counts require an inventory auditor or staff member to physically count all inventory items in stock at a specific time. From there, they can compare counts to the inventory data in point of sale systems and other inventory management methods. Companies usually perform physical inventory counts near the end of a fiscal year.

Physical inventory counts are straightforward at first glance, but they are generally very tedious and can even require the business to close so that inventory fluctuations stop while counts are performed. Shutting down shipping and receiving to complete this task can have long-term ramifications for contractors and manufacturers. What’s more, managers and supporting staff must dedicate extensive time to physical inventory counts, sacrificing work hours that could have been used for more strategic tasks.

Overall, physical inventory counts are rarely the most efficient route for accurate inventory auditing.

Cycle Counting: An Efficient Alternative

In many cases, inventory cycle counting is a more efficient method of performing an inventory audit. Cycle counting is an inventory audit method that breaks down inventory into smaller sections and counts the inventory in each section on a more regular basis. Cycle counting is the ideal method for tracking and replenishing MRO consumable supplies like cleaning products, breakroom materials, and stationery. There’s no need to pause normal business operations while cycle counts are performed, making it less disruptive than a physical inventory count.

Organizations can perform cycle counts on a regular basis to keep a more accurate and updated inventory overview, preventing errors from throwing off numbers in the long term. Teams can also leverage a wide range of methods to complete cycle counts, ranging from manual counts to more streamlined processes. Tools and software like barcode scanners and weight sensors under bins of product can make the cycle counting process extremely fast and accurate.

"We onboarded just under 1000 items and are adding more daily. eTurns customer service has gone above and beyond. TrackStock has decreased from 1 week to 1 day the time it takes us to do monthly physical inventory counts."

Performing an Inventory Audit

Performing a successful inventory audit requires careful planning, a strategic selection of technology, and team coordination. The accuracy and efficiency of an audit will come down to the tools you use and the level of planning you perform before you begin. Cycle counts are often easier to plan and coordinate than full physical inventory counts, and you can return to your plan again and again throughout the year for each cycle count.

Making a Plan

Jumping headfirst into an inventory audit without a comprehensive plan is more likely to result in frustration than clarity. Take the time to outline the objectives, scope, and methodology of your audit. Decide which inventory items will be audited, your specific goals around the audit such as identifying discrepancies with inventory records, and the details of your techniques for the audit.

Implementing Effective Inventory Audit Practices

Organizations can ensure effective inventory audit practices by establishing standardized procedures. These can take time to develop, but they help ensure consistency across all audits and cycles.

Every organization has unique inventory needs and will therefore benefit from their own specific practices and procedures for inventory audits. A contractor using point of use inventory management will have different audit requirements than a retailer or an EMS team, for example.

To implement an effective inventory audit process, begin with clearly defined roles and responsibilities for everyone involved in the audit. Look into your best options for tools and technology that can assist with a smooth and efficient audit, such as a barcode scanning app for inventory counts. Create a detailed schedule and communicate with all team members clearly for the smoothest possible process.

Best Practices for Physical Counts

To conduct effective physical counts, start by organizing the inventory in a way that makes counting straightforward. Create groups of similar items, ensure all items are properly labeled, and clear any obstructions that could slow down the process. Choose a schedule for physical counts that will cause the least possible disruption for your team and your business function.

In order to ensure your physical counts are as accurate as possible, get detailed about your approach. Build in cross-referencing between team members, a dual count system, or another method for double checking each other’s work. Physical counts are tedious, and it’s crucial to make them worth your time by making absolutely sure they are accurate. Keep a robust documentation system and compare your physical counts with inventory records so that you can look into any discrepancies and improve processes over time.

Leveraging Cycle Counts for Regular Validation

On a more frequent basis, teams can use cycle counts to validate inventory numbers and keep a closer eye on inventory accuracy without the need for disruptive physical counts. To perform regular cycle counts, begin by categorizing inventory items based on a consistent set of rules. You might categorize them by value, criticality, turnover rate, or location.

Create a cycle count schedule that ensures all inventory items are counted over a set period of your choosing. You may only need to count consumable inventory quarterly, or you may set up a monthly schedule for counting high-value retail items. The categories will help you create a schedule that works best for your specific needs, with high-turnover items counted more frequently.

Consistency is key with cycle counting. Use the same methods, documentation processes, and tools each time you perform a cycle count. It’s best to lean on inventory management software like eTurns to help you stick to your schedule, take accurate counts, and save time on every inventory audit. For example, TrackStock would notify you if you skipped counting an item that is scheduled to be counted.

"In the past, I spent at least two hours a day personally counting materials for the next day's jobs. With eTurns it only takes me 5 minutes every two weeks -- it gives me data on usage, quantity on hand, min/max levels and much more. And I like the ease-of-use."

Technological Innovations in Inventory Audits

Performing an inventory audit used to require careful manual counting, precise organization, and countless hours of staff time. Fortunately, new technological innovations are making inventory audits more efficient and accurate, saving time and resources for companies across industries.

The Impact of Inventory Management Systems on Inventory Audits

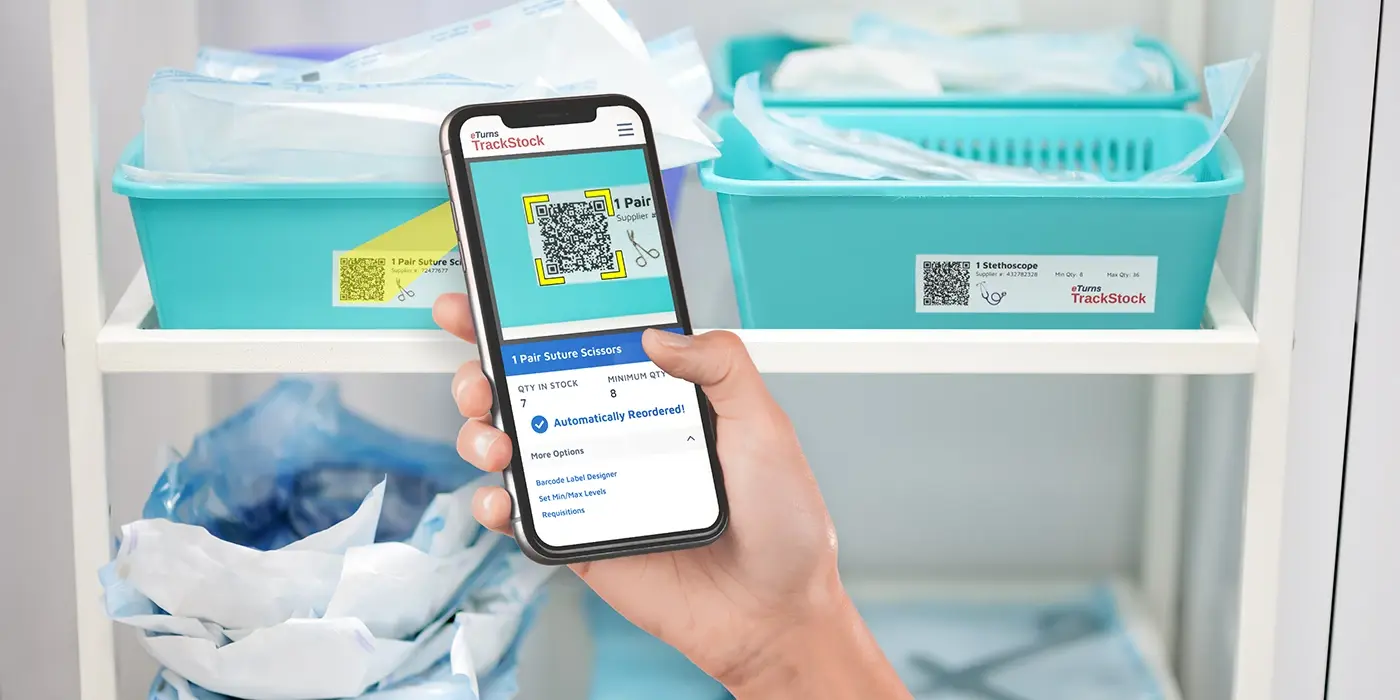

Organizations can use inventory management systems to cut back the amount of time it takes for them to manage their inventory while also reducing errors and stockouts. Inventory management systems allow for ongoing updates to inventory records that provide visibility of inventory status to both users and their suppliers. These systems provide features including inventory tracking and counting with easy barcode/QR code scans, automated inventory replenishment triggered by min/max levels, and detailed reporting. Customer-managed inventory apps like this make it easier to do inventory audits of point-of-use inventory in stockrooms, fulfillment centers, vehicles, conexs, clinics, etc.

Advanced Tools and Technologies

Organizations can gain a competitive advantage, reap labor savings, and gain a more thorough understanding of their inventory through the use of advanced technologies in the inventory audit process. For example, barcode scanning apps like eTurns TrackStock can greatly reduce the time it takes to do an inventory audit. TrackStock specializes in managing point-of-use inventory such as MRO, industrial, or medical items that are used in the course of business, not sold as retail or ecommece items. With one scan of a QR code, all the needed information on that item is already at the user’s fingertip for item counting, tracking, re-classification, and replenishment.

Here are other benefits of using the TrackStock scanning app for cycle counts:

- TrackStock helps you classify the items you wish to ABC cycle count (by value, usage, etc) and set min/max levels for each item.

- In real-time, TrackStock takes information from the cycle count and reorders items where minimums have been breached or re-classifies items where necessary.

- During a cycle count, the app lets you know if you missed counting an item in your scheduled count.

- TrackStock provides an alert dashboard that consolidates a to-do list, provides alerts, and creates analytics and visuals to create clarity and understanding around inventory.

No-touch cycle counts daily with weight sensors

TrackStock SensorBins use IoT weight sensors to do no-touch inventory tracking and can be set to measure the inventory levels several times a day depending on demand. For companies that have fast-moving or vital items that must always be on hand, especially on a manufacturing assembly line, SensorBins provide the best way to do cycle counts and the best insurance that items will always be in stock.

Challenges in Inventory Auditing

Without the appropriate tools and foolproof procedures, inventory auditing can be a frustrating source of errors, wasted time, and lost revenue. Many teams face challenges like inaccurate data entry or incomplete records that can pose a new set of problems once the inventory auditor team has made their counts. With the help of targeted technology, organizations can avoid some of the most common pitfalls of inventory auditing.

Common Pitfalls and How to Avoid Them

Since the traditional physical inventory audit format requires organizations to pause shipping and receiving, many people view inventory audits as an interruption to business operations. When this source of frustration blends with confusion over incomplete records or mismatched data, many teams feel understandably overwhelmed. Cycle counting systems and technology like scanners and sensors can help teams shorten the time it takes to do a complete physical inventory count and avoid these common pitfalls of inventory audits.

Remote Inventory Audits are Now Possible

In many cases, physical inventory audits no longer make logistical sense. Through the use of cloud-based inventory software and weight-sensors, remote inventory audits are finally possible so that teams can keep an accurate view of point-of-use inventory across locations around the world.

Tools like scanners and weight-basedsensors make it possible to automate much of the inventory management and auditing process. Adapting to these methods and technologies involves carefully selecting the right inventory management software for your specific needs, then thoroughly training all relevant team members on how to use it.

eTurns TrackStock: Key Differentiators

It’s important to keep in mind that all inventory management software is not equal. You’ll need to first look for an app that is designed to manage the type of inventory you have: point-of-use, retail, or e-commerce. The eTurns TrackStock app is designed to do VMI and CMI management and inventory audits of point-of-use inventory such as MRO inventory, industrial product inventory, and medical consumable inventory.

eTurns TrackStock is equipped with everything you need for a smooth inventory audit and optimized inventory management. Capabilities include:

- Guided cycle counts with a QR code/barcode scanning app

- Automatic digital reordering from any supplier if minimum thresholds are triggered on a count

- Usage tracking

- Min/max tuning to optimize inventory

- No-touch cycle counts with SensorBins weight sensors

Min/Max Inventory Solutions

Min/max inventory management is a strategy for keeping inventory levels within a specific range. Teams can set minimum and maximum quantities to ensure that inventory levels don’t fall close to stockouts but also don’t exceed necessary quantities and tie up cash in inventory.

Companies using min max inventory management can rely on the eTurns TrackStock AI Min/Max dashboard to optimize their min/max levels and to display possible savings if users adjust min/maxes to optimized levels. These capabilities allow for huge carrying cost savings as well. Dashboards can also send an emailed alert when item counts fall below the minimum or over the maximum and facilitate automated reorders.

Point of Use Inventory Management

Without the appropriate tools and software, point of use inventory management can be difficult to maintain, with a high potential for tracking challenges and inaccuracies across locations. eTurns TrackStock makes it possible to track, order, and analyze inventory levels across multiple points-of use.

Benefits of using a CMI inventory management app like TrackStock for doing on-site cycle counting and audits are:

- Perform ABC cycle counts more quickly - Use multiple options to categorize, segment and track inventory

- Notifications - TrackStock looks at variables such as quantity and price and reclassifies when necessary, notifying users of the change.

- Get alerts about missed items during scheduled counts

- Get alerts when it is time to perform a physical inventory or cycle count

- Flexibility - Users determine how items are classified and whether item orders or consumption is used to calculate inventory turns.

- Reporting - See potential discrepancies between customer count and current on-hand

- Do counts of consigned or customer-owned inventory

Hands-free Inventory Audits with SensorBins

TrackStock SensorBins™ provide physical inventory counts on demand in minutes with no human intervention - they are a no-touch IoT inventory replenishment system. Weight sensors under bins of supplies work together with TrackStock IoT cloud software for fully automated replenishment. TrackStock SensorBins™ convert bin weights to quantity on an ongoing basis to trigger automatic replenishment orders when needed, using min/max settings.

SensorBins are especially useful in medical or manufacturing locations that absolutely cannot stock out of items. They also are useful for distributors with VMI customers in remote locations because SensorBins can monitor item usage and optimize inventory replenishment 24/7/365 - they extend your salesforce.

Future of Inventory Management and Audits

As technology continues to advance and leveraging inventory management software becomes the norm among professionals, inventory audits will grow increasingly accurate and sophisticated. Teams will need to spend less time on inventory audits while enjoying more accurate counts and fewer discrepancies. The inventory issues like stockouts and overstocking that used to harm business operations and bottom lines will grow less and less common.

With every technological development, eTurns TrackStock prioritizes innovation and provides top-tier inventory management tools, paving the way for continued advancement. Get your free trial today!