Benefits of our Self-service CMI app

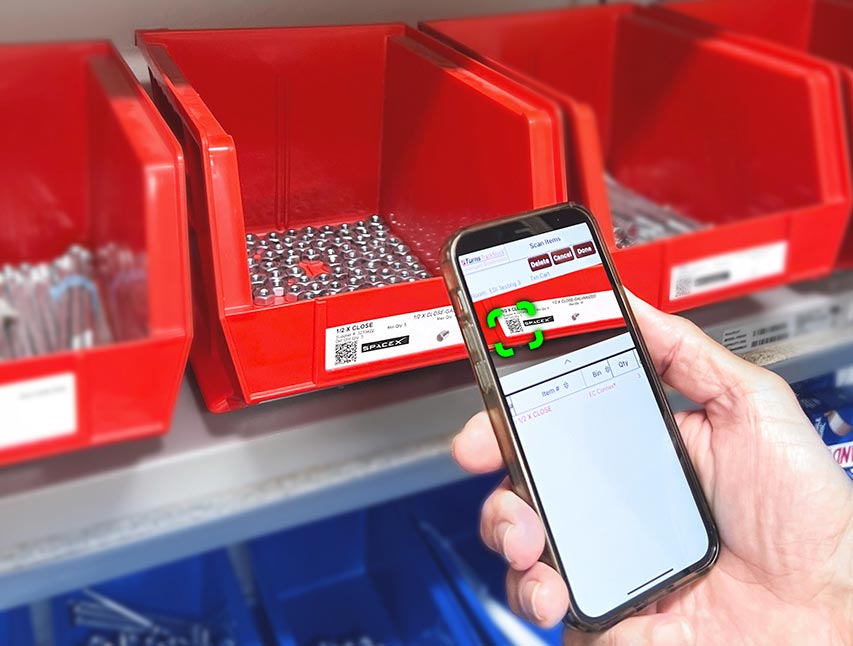

With TrackStock, inventory managers can place replenishment orders at any time on an as-needed basis in a self-service model using simple QR scans, electronic labels, SensorBins or RFID digital kanban. The CMI model allows businesses to track usage, do counts, or place orders accurately at any time instead of waiting for a supplier's monthly VMI visits. By tracking their own usage, they benefit from visibility into quantity-on-hand and from fewer upcharges for VMI services from suppliers.

Using TrackStock's QR code scans to order, count or track consumption is 4-10x more efficient than ordering with spreadsheets or ecommerce

Search Amazon's or any other distributor's entire product catalog through our app for easy orders

TrackStock offers cutting-edge technology for tracking: QR code scans, electronic shelf labels, RFID, and SensorBins

Ask your distributor for consigned inventory, because it will take inventory off your books and it can be tracked and billed accurately through TrackStock

Be up and running with TrackStock in an hour

Cost savings from the Customer-managed Inventory model

With TrackStock, the CMI inventory model can allow for a smoother replenishment process and prevent the distributor from tacking on upcharges to cover the cost of labor for in-person VMI replenishment.

The Min/Max Tuning Dashboard optimizes inventory levels after at least 45 days of tracking usage

Be up and running with eTurns in an hour

90% reduction in procurement costs from digitizing the PO process with scans at the point-of-use

Reduce PO costs by going paperless and reducing order entry. Send digital reorders directly to your suppliers' ERP systems or to your procurement system

"In the past, I spent at least two hours a day personally counting materials for the next day's jobs. With eTurns it only takes me 5 minutes every two weeks -- it gives me data on usage, quantity on hand, min/max levels and much more. And I like the ease-of-use."

Jason Baron

Field Operations Manage, M&L Electrical, a Graybar Customer